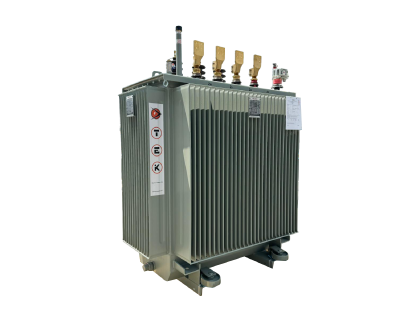

Power Grid Step-Down Distribution Transformers

Step-down distribution transformers are the backbone of medium-voltage power distribution systems, converting subtransmission-level voltages (up to 36 kV) to low-voltage levels suitable for end-user consumption. These three-phase, oil-immersed transformers are designed for installation in utility substations, industrial plants, and commercial complexes, and are manufactured according to IEC, or fully customized engineer-to-order (ETO) specifications. TEK Transformatör offers transformers in power ratings from 25 kVA to 3150 kVA, optimized for high efficiency, low partial discharge levels, and long service life under fluctuating load conditions.

Constructed with precision-wound copper or aluminum windings, step-lap laminated cores, and hermetically sealed or conservator-type tanks, our distribution transformers can be tailored with ONAN, ONAF, KNAN or OFAF cooling, off-circuit or on-load tap changers, and advanced protection accessories. Each unit is designed to meet stringent utility and industrial standards for dielectric strength, temperature rise, and mechanical short-circuit withstand, ensuring robust performance in diverse grid environments.

Technical Design Specifications

- Table 1. Product General Details

|

Power |

25–3150 kVA |

|

Primary Voltage |

400–36,000 V |

|

Secondary Voltage |

208Y/400 V to 14,400 V |

|

General |

|

|

Oil Type |

Mineral Oil or Natural Oil |

|

Impedance Voltage |

According to IEC (2.5%-10%) |

- Table 2. Environmental & Thermal Design Conditions

|

Standard Ambient Temperature Range |

−25 °C to +50 °C |

|

|

Extended Ambient Temperature Range (Optional) |

−45 °C to +55 °C |

|

|

Altitude |

||

|

Standard maximum altitude: ≤ 1000 meters (3280 feet) above sea level |

||

|

For altitudes > 1000 meters: Thermal derating will be applied (Derating factor: approx. 0.55% to 1,2% per 100 m) |

||

|

Insulation Class |

||

|

Class A (105 °C) |

Standard oil-paper insulation (mineral oil + cellulose paper) |

|

|

Class F (155 °C) |

Thermally upgraded paper or synthetic insulation; used in special applications or where higher temperature rise is acceptable |

|

|

Class H (180 °C) |

High-temperature-resistant materials (Nomex + silicone or ester fluids); used in compact or high-load designs |

|

Construction

- High-grade CRGO (Cold-Rolled Grain-Oriented) silicon steel cores with step-lap mitred

- joints for reduced no-load losses and low noise

- Optional amorphous metal core for ultra-low core losses (on request)

- Electrolytic copper or EC-grade aluminum windings with precision layer or disc winding

- configurations

- Windings insulated with thermally upgraded paper or high-temperature synthetic

- insulation (Class A, F, or H)

- Vacuum drying and impregnation under controlled conditions to remove moisture and

- enhance insulation life

- Reinforced bracing and clamping systems to withstand axial and radial short-circuit

- forces

- Core-coil assembly securely mounted with shock-absorbing supports to minimize

- mechanical stress during transport

- Fabricated from hot-rolled or cold-rolled mild steel or stainless steel, cut and bent using

- CNC precision equipment

- All welding performed according to EN ISO 3834 or AWS D1.1 standards, leak-tested

- and dye-checked

- Tank Types: Hermetically sealed, conservator type, or pressure-relief design

- External accessories include lifting lugs, valves, earthing pads, finwalls or radiator

- panels, and optional boxes

- Radiator surfaces sized to meet thermal performance at rated cooling class (ONAN/

- ONAF)

- High mechanical rigidity for safe operation under seismic or transport stress

Painting and Coating:

Surfaces prepared via grit blasting, phosphating and shot blasting for optimal adhesion

Multi-Layer Paint System: Zinc-rich epoxy primer, Polyurethane or polyester-based top coat

Coating Thickness: 105 - 240 µm (total DFT), suitable for C3, C4, or C5 environments per ISO 12944

Color Options: Custom RAL or Munsell colors available

Protection & Safety Features

- Integrated temperature indicators or bimetal thermostats

- Optional temperature sensors for real-time monitoring (Smart transformers)

- Pressure Relief Devices

- Liquid level indicators with float mechanisms

- Optional oil sampling valves

- Welded grounding pads and terminals for HV/LV compartments and tank

- Cable boxes on top or side of tank

- High mechanical strength design to withstand short-circuit forces

- Optional arc-resistant construction and compartment insulation

- IoT-enabled safety alarms for temperature, overcurrent, surge events

Let's Offer the Most Suitable Transformer Solution for Your Project

You can contact us to get more detailed information about Distribution Transformers, receive consultancy services on technical specifications, or request a special offer for your project.